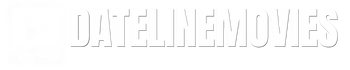

In a world where even a tiny measurement error can lead to wasted materials, failed medical tests, or faulty products, the need for perfect accuracy is greater than ever. This is where Kalibraatio, the Finnish term for calibration, comes in. Calibration refers to the process of verifying and adjusting a device so it provides correct and dependable measurements. People often search this term when working with technical tools or trying to understand why their equipment is giving inconsistent results. In industries where precision is everything, it isn’t just routine; it’s essential.

Table of Contents

How Does Calibration Actually Work?

Calibration works by comparing a device’s reading to a trusted, internationally recognized reference standard. If the device shows a different value, it is adjusted until the readings match the standard. This process typically involves:

- Checking the current measurement accuracy

- Identifying the error or drift

- Correcting the device to align with the reference value

- Documenting the calibration results

Example:

If a digital scale shows 1.2 kg when a certified 1 kg weight is placed on it, measurement precision fixes this mismatch and resets the device to show 1 kg exactly.

Why Is Calibration Important in Modern Industries?

It plays a critical role in industries where precision affects safety, product quality, and trust. A slight deviation can cause major problems, such as incorrect medicine dosage, defective machine parts, or scientific errors.

Industries rely on error correction to:

- Maintain consistent product quality

- Meet legal and safety regulations

- Avoid financial loss from inaccurate measurements

For example, in medical labs, an improperly calibrated metrology analyzer could produce wrong blood test results, putting patients at risk.

ALSO READ: 5 Features That Make BinusCX a Game-Changer for Students

What tools or instruments do you need?

Many everyday and industrial tools require regular error correction, including:

- Home devices: thermometers, weighing scales, pressure meters

- Industrial equipment: torque tools, flow meters, sensors

- Scientific instruments: microscopes, pipettes, spectrometers

How Often Should Calibration Be Done?

It frequently depends on how frequently the device is used, the environment it operates in, and the accuracy level required by the industry. High-precision tools, such as laboratory instruments or medical devices, may require it monthly or before every critical use. Industrial equipment is often serviced according to manufacturer-recommended intervals, typically every 6–12 months. Failing to follow proper equipment adjustment schedules can lead to gradual measurement drift and costly errors over time.

Is it done manually or with machines?

It can be done manually by a trained technician or automatically using advanced equipment adjustment systems.

- Manual calibration is used for tools that require human judgment or specific adjustments.

- Automated calibration systems are common in large industries, reducing human error and improving consistency.

Industries like pharmaceuticals, aerospace, and automotive manufacturing rely heavily on automated IT systems to ensure precise, repeatable results.

Signs Your Device Needs

- Inconsistent results from the same measurement

- Drifting values over time

- Performance issues like slow response or fluctuating readings

- Mismatch between known values and measured values

Example:

If your home scale shows a different weight each time you step on it, even within seconds, that’s a clear sign it needs error correction.

Common Mistakes People Make During it

Many equipment adjustment errors occur when users rely on unverified reference standards or perform equipment adjustments in unstable conditions, such as fluctuating temperature or vibration. Another common mistake is skipping the manufacturer’s guidelines, which can lead to incorrect adjustments. Failing to record error correction data also creates long-term issues, making it difficult to track performance or detect measurement drift.

Real-World Use Cases

1. Healthcare

Calibration ensures medical devices like ECG machines, blood analyzers, and infusion pumps deliver safe and accurate results.

2. Manufacturing

Factories calibrate torque tools, sensors, and measuring gauges to maintain consistent product quality and meet industry standards.

3. Laboratories

Micropipettes, balances, and temperature devices must be calibrated to guarantee reliable scientific data.

4. Aviation

Flight instruments require precise calibration to ensure safety and reduce risks during flights.

FAQs

1. What happens if you never calibrate a device?

Over time, the device becomes unreliable, leading to costly errors, faulty results, and potential safety risks.

2. Does calibration increase the lifespan of a device?

Not directly, but it ensures the device continues performing accurately and safely throughout its lifespan.

3. Is it the same as maintenance?

No. Maintenance keeps a device functioning; it ensures it measures correctly.

Final Thoughts:

Calibration is more than a technical step; it’s a commitment to accuracy, safety, and quality. Whether you’re in manufacturing, healthcare, research, or everyday use, it ensures your tools deliver trustworthy results. In a world built on precision, it helps prevent errors before they become problems and keeps every measurement aligned with reality.